products & services

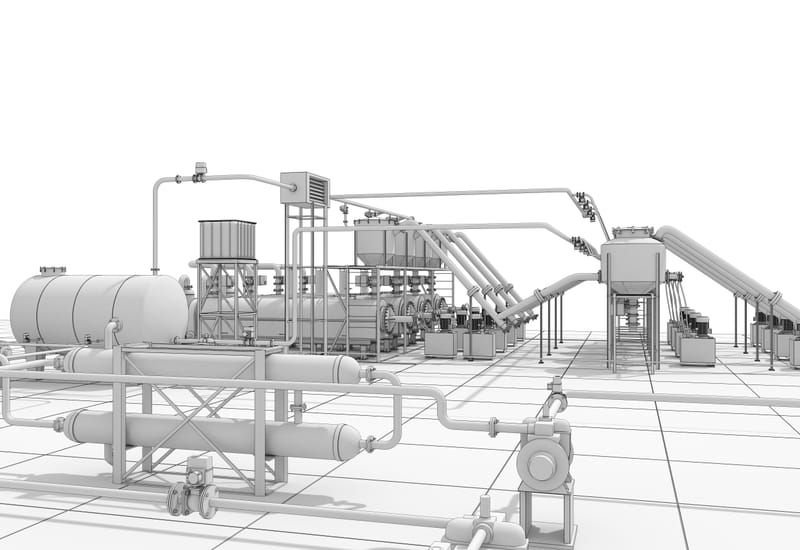

Separation Equipment for Demanding Industrial Applications

We are a leading provider of state-of-the-art separation equipment technology that delivers exceptional performance and reliability. Our extensive separation equipment range includes conventional mist eliminators, vane packs, cyclones, various inlet distributors, and plate pack coalescers. Some of our advanced technology includes next-generation axial flow cyclones developed to maximise separation efficiency and operating range. Our advanced separation equipment is crucial for efficient fluid separation in industries such as oil and gas, chemical processing, and mineral processing. We are fortunate to leverage the latest technologies and industry best practices to design and manufacture separation equipment that meet the highest standards of quality and performance. When you choose MTT, you can be confident that you are purchasing quality products that will meet or exceed your performance criteria.

Learn More

Produced Water Upgrades

Built around a patented coalescence process chamber, we offer solutions that are supplied in stand-alone compact flotation unit skids or used to upgrade and improve the efficiency and capacity of existing oil-water separation systems. Existing underperforming separation vessels or systems can be upgraded by retrofitting the Stauper coalescence chamber into the vessel or system. This upgrade will significantly improve oil from water separation, and degassing of the water while improving flow capacity. As a result of this upgrade our clients can expect improved separation performance a reduction in the need for costly chemicals and significantly improve the environmental footprint.

Tower Internals

We offer innovative solutions for mass transfer operations based on our extensive experience. We have developed cutting-edge separation equipment and systems that are at the forefront of mass transfer applications. Our advanced mass-transfer equipment and technologies are designed to deliver optimal performance. In addition, we provide a range of cost-effective services, including design, engineering, procurement, project management, and construction, to support various mass-transfer operations such as conventional and complex distillation azeotropic and extractive distillation liquid-liquid extraction absorber and stripper systems reactive distillation systems We are committed to meeting the unique needs of our clients by offering comprehensive solutions, from conceptual design to debottlenecking existing columns and complete process plant modernisation. Our expertise extends to the design and supply of various tower internals. Whether you require conventional trays, high-performance trays, random packing, structured packing, grid packing, or packed internals for distillation, absorption, stripping, and extractive distillation columns, we have you covered.

Learn More

Falling Film Evaporators

Falling film evaporators are employed in industries ranging from food and beverage production to pharmaceuticals and fine chemicals. They operate on a simple yet ingenious principle: a thin, continuous liquid film flows downward inside vertical tubes, while heat is applied to the exterior surfaces of these tubes. Controlled heat application causes the liquid to evaporate, forming vapour that rises upward, separating it from the concentrated liquid below. This efficient method maximises the surface area available for evaporation and minimises residence time and exposure to heat, thereby preserving the delicate characteristics of the product being processed. In the food and beverage sector, they play a crucial role in concentrating juices, reducing milk, and extracting flavours and essences with minimal thermal degradation. In pharmaceuticals, these evaporators are used for producing concentrated active ingredients and isolating pure compounds. Similarly, in chemical processing, they facilitate the separation and purification of various fine chemicals, contributing to the production of high-quality fine chemicals and intermediates.

Learn More

Engineering Design, Optimisation & Troubleshooting

We understand the importance of efficient and reliable engineering solutions and equipment. That is why our team of experienced engineers is dedicated to providing industry-leading services and equipment that cater to our client's unique separation requirements. From specialist separator and equipment design to process simulation, feasibility studies, front end engineering and design (FEED) to process optimisation and troubleshooting, we have the expertise and tools such as process simulation, computational fluid dynamics (CFD), finite element analysis (FEA) and structural analysis software to deliver effective solutions that improve performance, reduce downtime, and enhance overall efficiency. MTT is a reliable partner that books specialist outcomes not hours preventing project cost blowouts and minimising risk.

Learn More